With a strong ability in performing scientific research, development, design, manufacturing, engineering and service of energy saving and air pollution control equipment, SMDERI owns a great many patent and proprietary technologies and has become the first Chinese supplier of flares, boilers, screw machinery, etc. The products supplied by SMDERI have reached advanced international level and are widely used in oil refining, petrochemical, chemical, coal, shipping and other industries. Now SMDERI shares over 70% market in China and has successfully entered USA, West Asia, South-east Asia and other international markets.

Focused on the research in combustion and thermal engineering fields for decades of years, SMDERI has successively developed a lot of new type of air pollution control equipment, such as column type pulverized coal gasifier, special burners, new efficient heat exchanger, flue gas expander, low-grade heat thermoelectric conversion technology and related device, vapor recovery unit, in support of the transformation and upgrading of related industrial products.

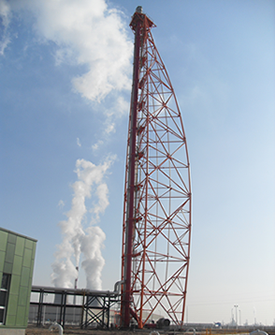

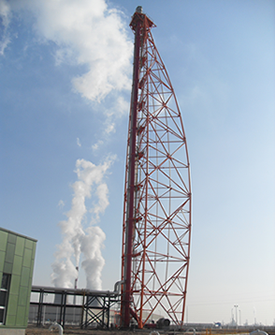

Flare & flare gas recovery system

SMDERI started the R&D of flare system and has taken the lead of the technical progress and development in the flare & flare gas recovery industry in China. We provided satisfactory service in proposal verification, engineering, EP and EPC service for many users. We has been the authorized vendor of many international and Chinese companies ranking top 100 companies internationally and large private petrochemical enterprises and the products have been installed in South Korea, Pakistan, Myanmar, Iraq, Turkmenistan and Venezuela.

Waster heat boiler

Our projects include Catalytic cracking unit waste heat boiler, Catalytic cracking unit waste heat boiler with flue gas desulfidation & denitrification device, Waste heat boiler of modularized structure, Water-heat-medium air preheater, Heat pipe Economizer gas and Hydrogen boiler.

Heater

As an important heating device for various production units in oil refining, chemical, fertilizer, chemical fiber and other industries, heater usually consists of five subsystems, namely a radiation chamber, a convection chamber, a waste heat recovery system, a combustion system and a ventilation system. Considering diversified heater types and configurations and varied medium property and technical parameters, how to design the heater in a proper way and optimize the heater structure motivates the continuous improvement of heater technology.

Waste gas & liquid thermal oxidizer

Our projects include Waste gas & liquid thermal oxidizer, Regenerative thermal oxidizer cracking, Catalytic incinerator heat and Water-heat-medium air preheater.

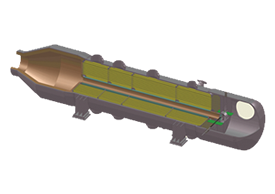

Pulverized coal gasifier

As a critical equipment of coal gasification unit, the column type coal gasifier is a pulverized coal gasifier with waste heat boiler flow (patent No.:200810035341.7). The syngas cooler and reactor is co-axially arranged in a pressure vessel, which simplifies the gasifier construction.

Methanator unit

During the natural gas production with coal, CO and H2 in the syngas will react in multiple sections of methanator reactors and produce methane. The methanization reaction is a strong exothermic reaction and thus waste heat boiler is to be arranged between two methanator reactors in order to control the syngas temperature.

Burner

As the clean coal technology develops rapidly, SMDERI takes the opportunity to embark on the modern coal chemical industry market. After 8 years of efforts, SMDERI has established a strategic base for the R&D, fabrication and maintenance of modern coal burners. The base is furnished with a large multi-purpose test platform for high pressure pure oxygen combustion and a burner work shop with complete advanced equipment for machining, welding and inspection. Now the base has obtained ISO9000, ISO14000 and ISO18000 certificates. And SMDERI has set up a technical force made up of professional technical personnel with post-doctorial, master, senior engineer and senior technician titles.

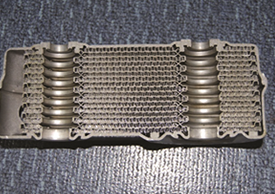

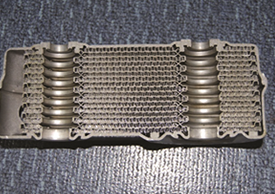

Heat Exchanger

As the institute responsible for the R&D of marine heat exchangers, SMDERI has the largest oil-water and air-cooler test laboratory in China. We has a complete set of production line and can supply a portfolio of efficient heat exchanger, including: Block-type fully-welded plate heat exchanger、Plate & Shell heat exchanger、Plate heat exchanger 、Plate-fin heat exchanger、Twisted tube heat exchanger、Air cooler、Shell&tube heat exchanger.

Vapor recovery unit

SMDERI adopts adsorption type vapor recovery process and is to provide high quality vapor recovery unit and related technical service. By changing over 99% composition in the vapor into liquid product, Such technology can effectively prevent the hazard caused by direct discharge of vapor into atmosphere, recover useful products and create considerable benefits for user and therefore, is widely applicable in various case with volatile gas to be recovered.

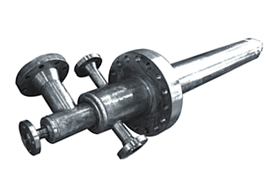

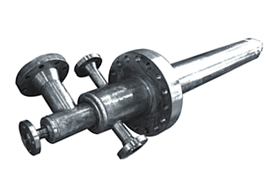

Submerged combustion vaporizer

The main functional routes for typical SCV system researched and designed by SMDERI are peak shaving, supplement, and emergency handling. The LNG flows through a stainless steel tube coil that is submerged in a water bath which is heated by direct contact with hot flue gases from a submerged gas burner. Flue gas is through into the water using a distributor located under the heat transfer tubes. It is cannot use SCV unit to gasify the LNG at the winter season or cold areas because of the sea water temperature is lower, at this time we need to switch the gasification model, and it will start immediately. The first SCV unit designed by SMDERI is applied in Jiang Su LNG import terminal, and the capacity is 200t/h, which the quantity of gasification can adjust from 10%~100% of loading and the SCV unit can give the response when the load suddenly changed.

Low-grade heat application technology

Utilization of low-grade heat is always a key approach to solve energy problem, and also an intractable nodus. The technology in the field of low-grade heat application of in SMDERI comprises Low-grade heat thermoelectric conversion technology and heat pump technology, and is very suitable for recovery low-grade waste heat in petrochemical, steel, cement, glass, electrolytic aluminum and other fields. SMDERI is dedicated to provide high quality low-grade heat application equipment and solutions.

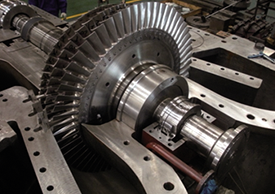

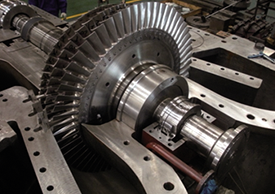

Expander

SMDERI has employed the aero engine technology for aerodynamic design and 3-D tools for structural design, which boosts the efficiency of energy recovery and significantly reduces the air erosion and fouling problem of blade, and therefore guarantees the stable operation in the long term. SMDERI is delivering expander which could more efficiently collect and reuse the energy in exhaust gas and therefore keep the 3-in-1 or 4-in-1 nitric acid production unit running at design speed and guarantee the productivity.

Screw compressor

Screw compressor produced by SMDERI is a kind of pressure boosting device. Its process gas is alkane, H2, H2S, butadiene, VCM, CO2,CO and other flammable, explosive, easy polymerization or corrosive gas. These devices can meet the requirements of the gas which has dust and liquid. Till now, more than 700 sets screw compressors are widely used in crude oil stabilizer, flare gas, atmospheric and vacuum distillation unit, styrene production, butadiene device (DMF method & oxidative dehydrogenation method), catalytic reforming and dry gas PSA, alkylbenzene production device, UOP aromatics plant, propane dehydrogenation device, offshore platform etc..

Screw Expander

Screw expander produced by SMDERI is a kind of energy recovery device. It’s suitable for steam, hydrothermal, gas liquid two-phase and low boiling point organic medium, etc. These devices can be set at any place where there is residual heat, pressure and waste energy , and convert the waste heat into electricity. It is widely used in petrochemical, power, steel, metallurgy, cement, printing and dyeing, papermaking, pharmacy, food, heating and other fields, not only for cities, but also for township enterprises. At present, 3 series of screw expanders have been designed in accordance with different medium, which are known as the steam power screw expander, the process gas screw expander and the low-temperature heat screw expander.